THERMAL

IMAGING

INSPECTIONS!

Certified Infrared

THERMOGRAPHY SUPPORT TEAM

THERMAL IMAGING

INSPECTIONS!

Certified Infrared

THERMOGRAPHY SUPPORT TEAM

INTRODUCTION

We provide thermal imaging and maintenance solutions to help businesses detect, prevent, and repair electrical and mechanical issues—ensuring safety, efficiency, and reliability while minimizing downtime and costly failures.

Infrared Thermography Applications

Electrical Systems

Detect overheating components

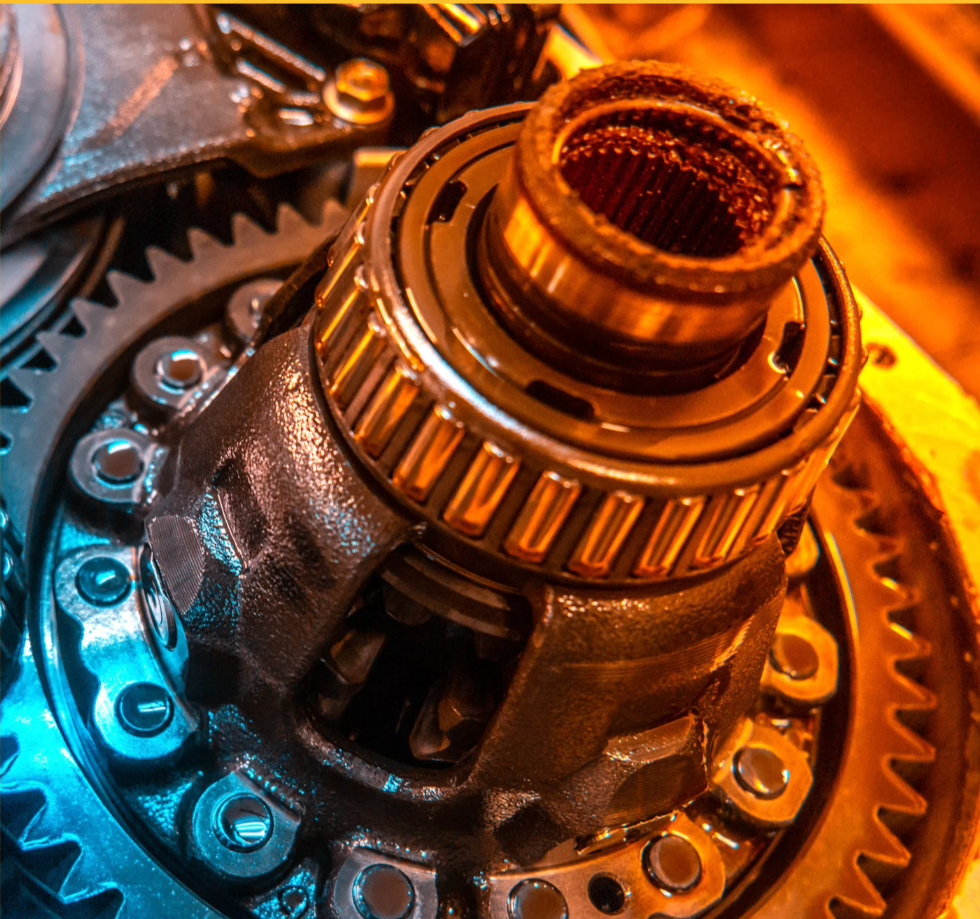

Mechanical Equipment

friction, misalignment, or failing Mechanisms

Hvac

Ensure efficiency. blockages, leaks & failing components.

Building Inspections

hidden moisture, insulation gaps, and structural weaknesses.

Roof and Insulation

heat loss, water intrusion,compromised insulation.

Industrial Processes

optimize production and prevent failures.

Beyond Detection: Repair & Maintenance Services

Identifying issues is just the first step—we go further by providing comprehensive repair and maintenance solutions to fix problems before they lead to costly failures.

Our services include:

- Expert repairs for electrical and mechanical issues found through thermal imaging.

- Preventative maintenance to ensure long-term system efficiency.

- Custom solutions tailored to your facility’s needs.

Prevent Issues Before They Escalate

Infrared thermography helps identify hidden electrical faults before they cause costly failures. Our inspections detect:

- Overheated connections

- Circuit overloads

- Loose or deteriorating components

- Imbalanced electrical loads

With early detection, you can prevent breakdowns, reduce downtime, and extend equipment lifespan.

Prevent Issues Before They Escalate

Infrared thermography helps identify hidden electrical faults before they cause costly failures. Our inspections detect:

- Overheated connections

- Circuit overloads

- Loose or deteriorating components

- Imbalanced electrical loads

With early detection, you can prevent breakdowns, reduce downtime, and extend equipment lifespan.

Systems and Tools

Thermal

Inspection

Step 1

Analysis &

Reporting

Step 2

Repair &

Maintenance

Step 3

Ongoing

Monitoring

Step 4

Need help setting up?

office

1 855-608-0178

Monday 8-6

office

1 855-608-0178 Monday 8-6

info@powerblitz.ca

Chat

Click the chat button below